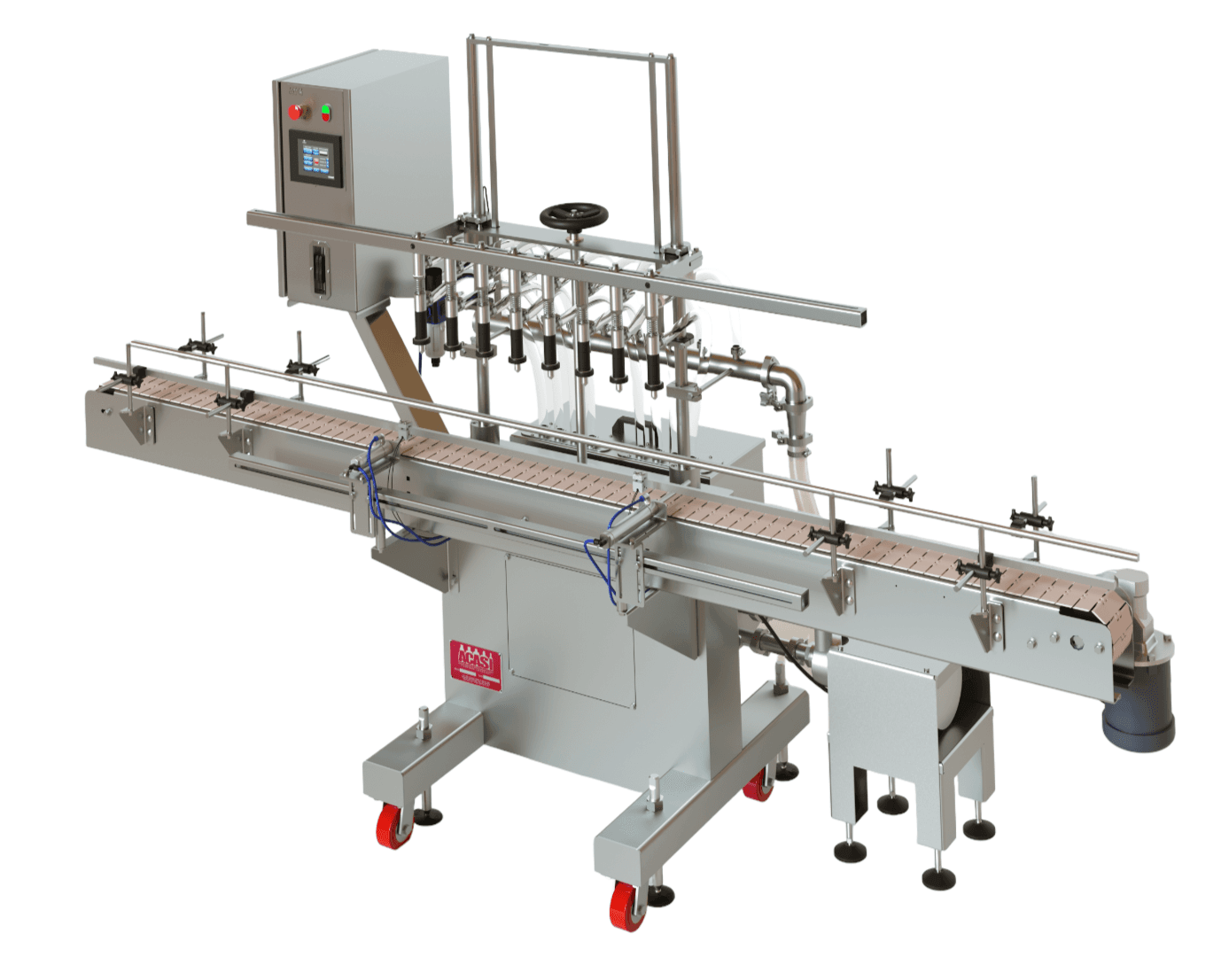

ACASI GI 3300

ACASI GI 3300

Model GI 3300 – The pressure overflow filler fills the container with the product to a predetermined level. It uses an overflow nozzle with two tubes, one for the fill and the other for the return.

Pressure Overflow Bottle Filler – Model GI 3300

Construction features:

- 304 Stainless steel heavy duty stainless steel welded C frame.

- 20 Gallon stainless steel overflow tank.

- Stainless steel cover for overflow tank.

- 20 hose 304 stainless steel feeding manifold.

- All contact parts are stainless steel, sanitary, Teflon, viton and hoses per your requirements.

- Special seals or hoses by order.

- Calibrated guide for fast height changeovers.

- Filling machine mounted on 4 heavy duty casters.

- Leveling of machine by 1 inch 304 stainless steel leveling screws.

Control panel features:

- Omron PLC for all machine logic functions, special modifications on programs available for special adaptations.

- Frequency control drive for pump speed, acceleration and deceleration.

- Front panel bottle filling time adjustment through Omron Timer.

- Front panel conveyor speed control for machine sold with conveyor.

- Front panel mounted bottle counter.

- Front panel Start and Emergency STOP for easy access.

- Front panel nozzle code for changing nozzle quantities.

- Fiber optic sensors by Omron standard for container gating.

- Expandable to 20 nozzles to increase speed.

- No bottle no fill PLC controlled.

Main components features:

- 96 Gallon per minute, 1 Hp, 3phase, 316 stainless steel centrifugal pump.

- Hardened Stainless steel calibrated shafts with linear bearings for nozzle rack movement smoothness and durability.

- 10 inch stroke air cylinder with magnetic sensors for nozzle up and down movement.

- 316L Stainless steel sanitary check valve mounted on pump.

- Hand wheel and shaft mounted stoppers for height and stroke adjustment.

Standard features:

- Nozzle spacing fully adjustable through top screw.

- Container height adjustment from 1 to 16 inches high.

- Nozzle stroke adjustments from 0 to 10 inches.

- Entry and exit bottle gating cylinders adjustable, sideways, up and down and inside and outside.

- Will work with plastic or glass containers.

- No change parts needed for various types of containers.

- Air filter-regulator and safety lockout valve included.

- Spacing and additional bottle control obtained by flow controls mounted on air gating cylinders.

Electric and pneumatic requirements:

220 Volts, 60Hz, 10 Amps.

5 CFM @ 80 p.s.i.